WINDOWS10

cubexpackaging.com

mandalaperfumeriamistica.com

aidaintensive.dance

decofixindia.com

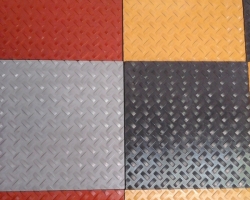

PAVER BLOCKS is a commonly used decorative method of creating a pavement or hardstanding. The main benefit of bricks over other materials is that individual bricks can later be lifted up and replaced. This allows for remedial work to be carried out under the surface of the paving without leaving a lasting mark once the paving bricks have been replaced. Typical areas of use would be for driveways, pavement, patios, town centres, precincts and more commonly in road surfacing. Bricks are typically made of concrete or clay, though other composite materials are also used. Each has its own means of construction. The biggest difference is the way they set hard ready for use. A clay brick has to be fired in a kiln to bake the brick hard. A concrete brick has to be allowed to set. The concrete paving bricks are a porous form of brick formed by mixing small stone hardcore, dyes, cement and sand and other materials in various amounts. Many block paving manufacturing methods are now allowing the use of recycled materials in the construction of the paving bricks such as crushed glass and crushed old building rubble.

There are many different laying patterns that can be achieved using block paving. The most common of these is the herringbone pattern. This pattern is the strongest of the block paving bonds as it offers the most interlock, therefore making it a good choice for driveways and road surfacing. A herringbone pattern can be created by setting the blocks at either 45 degrees or 90 degrees to the perpendicular. Other popular types of pattern include stretcher bond and basketweave; with the latter being better suited to paved areas that will only receive light foot traffic, due to its weaker bond.

Concrete Pavers

Pavers manufactured from concrete go well with flag, brick and concrete walkways or patios. If you reside in climates wherever winter temperatures dip below zero, concrete pavers are an honest selection. They are ready to stoppage well in extreme temperatures. Opt for pavers in shades like ochre, pink, bisque, white or sand. Pavers are available in hole, x-shape, y-shape, pentagon, polygon and fan styles.

Advantages of Block Paving

There is a wide range of styles, types, colours and sizes of block pavers hence there are also many design possibilities.

Block paving is considered to be more attractive than basic, plain tarmacadam surfaces for driveways.

Block paving can be relatively inexpensive if you choose the basic rectangular blocks. One major block paving manufacturer estimates the costs as being split 20% blocks, 80% labour, hard core and sand. Basic blocks can be purchased from £8 or £10 per square metre up to over £20 per metre, so overall costs should be between £50 and £100 per metre. However, complex patterns and additional items such as edging, steps and drainage can be added to these figures.

Individual blocks can be lifted and replaced if they are damaged, or stained with oil, diesel or petrol spillages.

Because paving blocks are manufactured rather than cut from natural stone, block sizes tend to be very accurate and uniform.

No specialist machinery is required (as there is with tarmacadam surfaces) hence small areas should not be proportionately more expensive per square metre, as when there are high set-up costs.

Concrete block paving is cost effective when compared to clay pavers or natural stone blocks such as granite sets.

There is a wide choice in the depths of concrete block pavers from 50 mm to over 100 mm. This can make block paving suitable for both domestic and commercial applications.